Fabrication

Fabrication is the execution of a plan. To be efficient in the execution, you have to have three things: capability, talent, and inspiration. We have all three. At Zephyr we have an extensive number of capabilities. In fact, we are continually searching for new equipment and methods to help us be more efficient while increasing our capability and capacity. We have a full complement of fabrication equipment in-house, including everything from flat and rotary lasers to cnc sheet forming and tube bending. It’s all at your disposal.

Our team of experts know how to work efficiently while keeping quality high. Ultimately, this saves you money. Better parts, faster, and less expensive.

Check out some of the tools and processes we use to provide full service, one-stop fabrication to meet your needs. Give us a call, we would love to see how we can serve you and meet your fabrication needs.

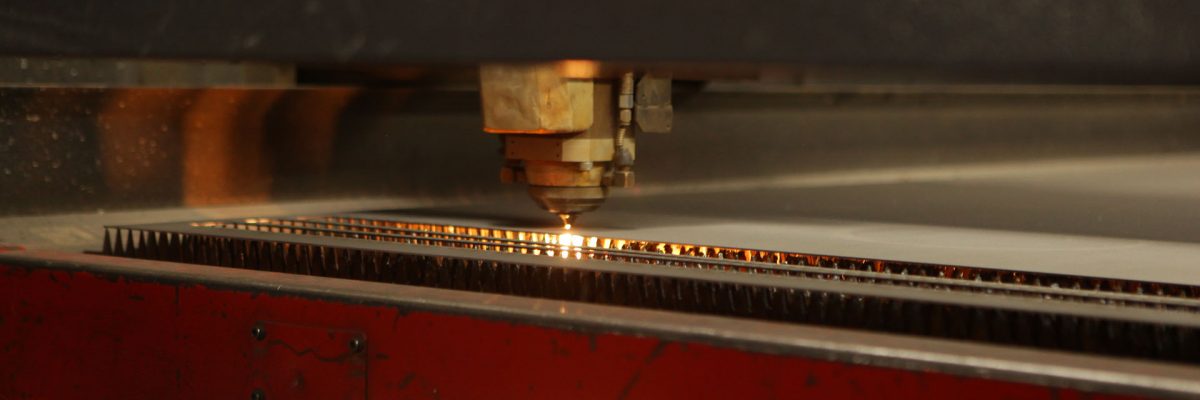

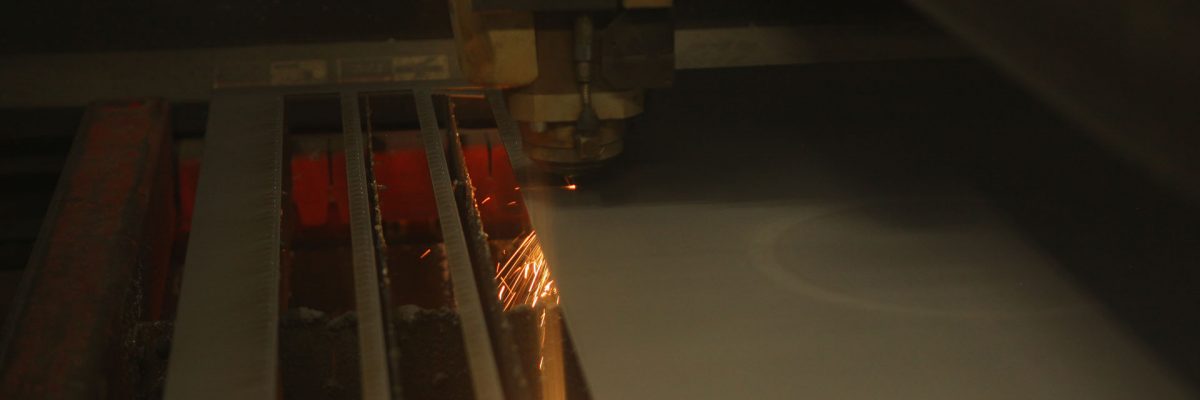

We have two 4,000-watt lasers equipped with advanced optics designed to facilitate precise, efficient, and repeatable cutting. This enables us to consistently provide high quality, clean product up to 1.00″ mild steel and 0.500” aluminum and stainless. In addition to laser cutting, we provide etching and part-marking services.

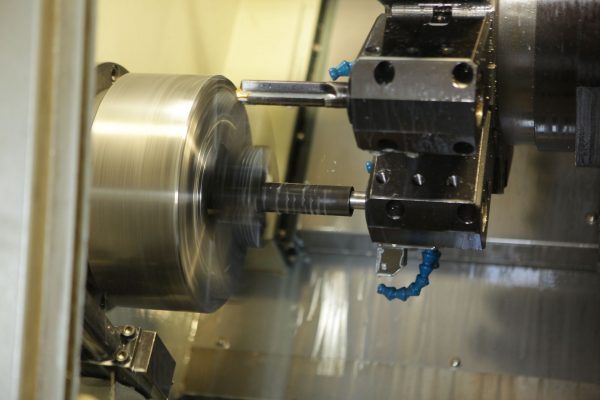

Structural lasering available on several different shapes and styles of material including round, square or rectangle tube, angle, and channel.

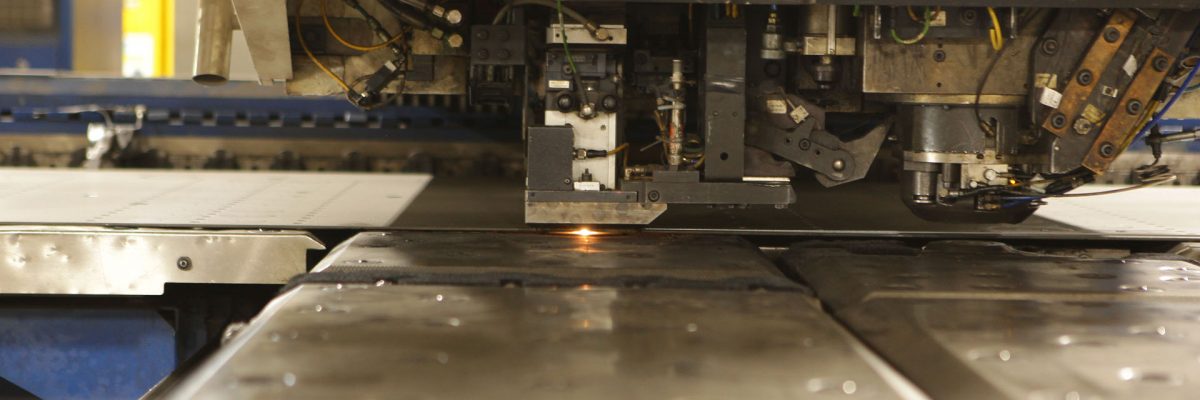

Our 3200-watt laser punch combo allows us to provide parts with extrusions and louvers, with a clean and precise laser-cut edge. With the addition of automation, the LPC offers the ability to load and unload sheets and palletize parts at the touch of a button so we can save you money while providing exceptional quality.

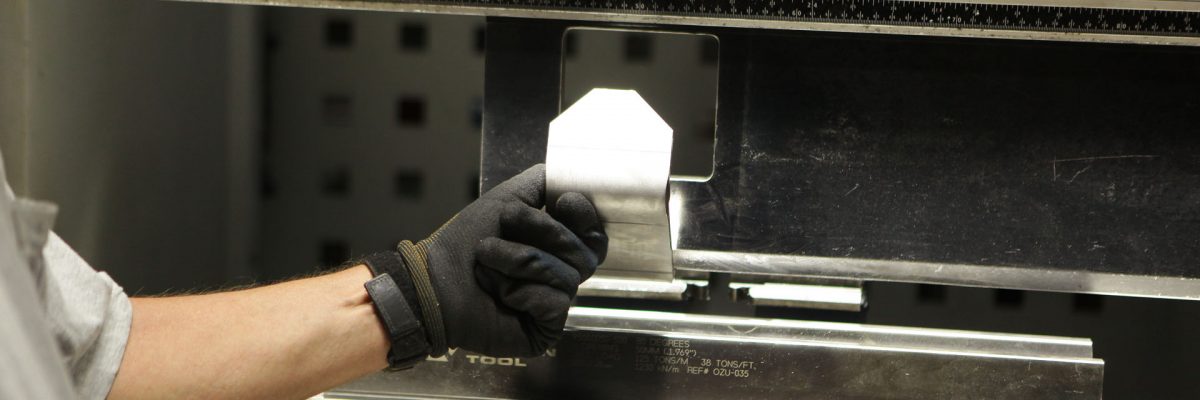

Our programmable press brakes can form material up to 14 feet in length. The CNC programming allows us to provide repeatability and accuracy while minimizing set-up costs by using quick change tooling.

With up to 5,500 lbs. bundling or individual cutting capabilities, multiple lengths can be programmed for each bundle to reduce cost per cut. Miter cutting is also available.